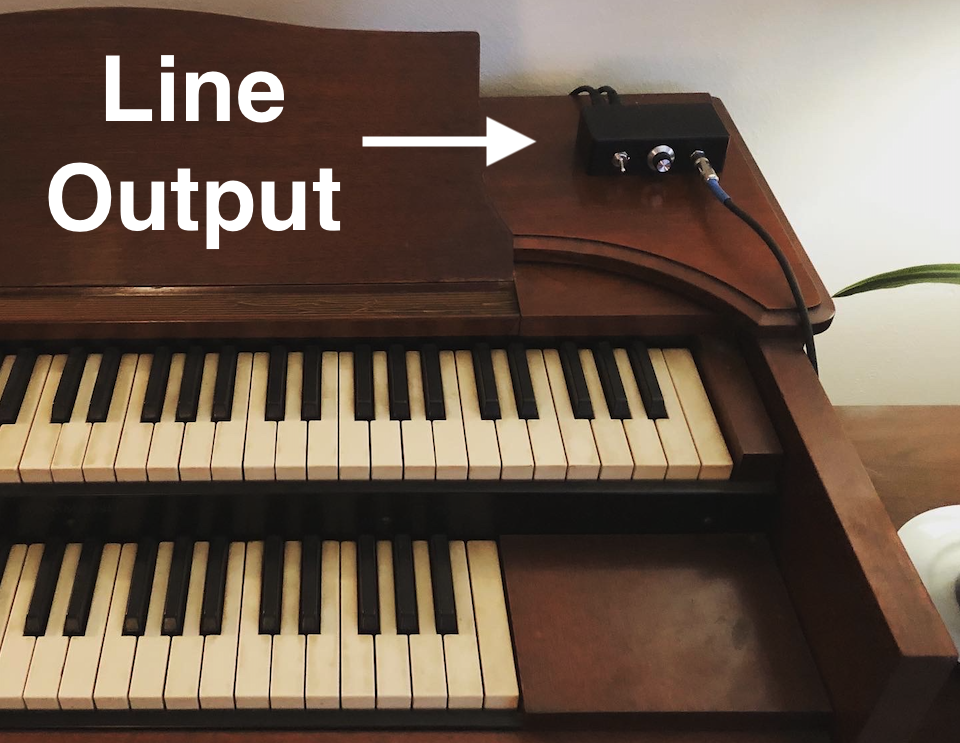

Building a Line Output for a Hammond M3 Organ

The Hammond M3 organ is widely loved by many organ and synth enthusiasts for both its incredible authentic Hammond tones as well as its relative portability (as compared to its iconic and colossal brother the Hammond B3).

But unfortunately, besides the built-in speaker, there is no built-in output. This can make it difficult to send output directly to recording software, a PA system, or through effects units.

Luckily, with a few cheap components and a soldering iron, you can make your own line output!

How it works

The method used in this tutorial will take the output signal directly from the speaker wires. This means the only real modification that needs to be done to the organ is cutting & splicing these two wires. It also means that the signal level will need to be reduced pretty significantly since we’re taking it from after the power amp. This can be done with a simple resistor and capacitor in series.

At it’s simplest, that’s really all you need to make a working line output. But to make it a little more practical, I also included a volume knob and a switch to enable/disable the onboard speaker. The line out will work regardless of whether the onboard speaker is on, and it’s nice to have the option.

It’s important to note that this switch is not just cutting the signal to the speaker, it’s actually replacing the speaker with a power resistor, which acts as a “dummy load”. To the amp, this resistor looks and behaves like the speaker would, it just doesn’t make any sound. This is especially important for older tube amps as they were generally designed to run with a specific load and can actually incur significant damage if there is no load at all.

That’s about it! As far as mods go, this method is pretty straightforward and requires minimal changes to the organ itself.

Materials

Components:

- 1 Enclosure (plastic recommended)

- 1 10′ RCA Cable

- Heat shrink tubing (recommended, but you can also use electrical tape)

- 2 Female RCA Jacks

- DPDT On/On Toggle Switch

- 1 8Ω 10 Watt Power Resistor

- 1 1kΩ Resistor (1/8 or 1/4 Watt)

- 1 10µf Electrolytic Capacitor

- 1 A50K Potentiometer (Audio Taper)

- 1 Potentiometer Knob

- 1 1/4″ Stereo/TRS-style Jack

- Wire

Tools:

- Soldering Iron & Solder

- Wire Stripper

- Drill

Step 1: Drill the Enclosure and Install Components

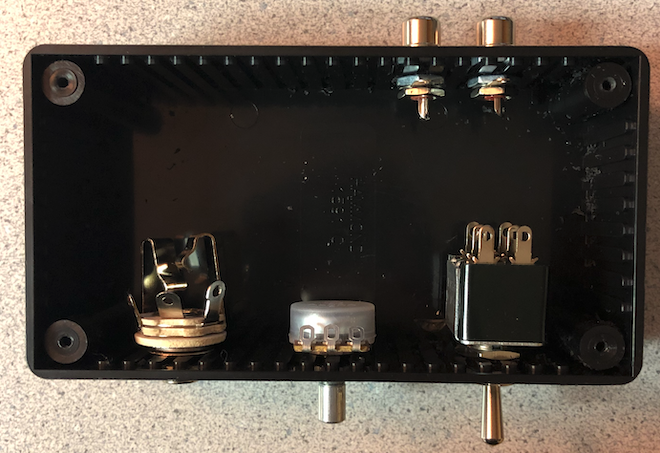

After you collect the required materials above, the first step will be to drill some holes in your enclosure. I personally used a plastic “1590B”-style enclosure (as pictured) but you can choose anything that will fit all your components.

Note: a plastic enclosure is recommended so that the outer contacts on the RCA cables do not short via a metal/conductive enclosure. You can probably get away with a metal enclosure as long as you make sure to insulate your RCA jacks from one another.

I more or less “eyeballed” the locations for the holes but feel free to break out the old ruler and pencil here if you want yours to look nice and professional. Make sure to measure the diameters for each of your components before drilling their respective holes. Then, get to drilling!

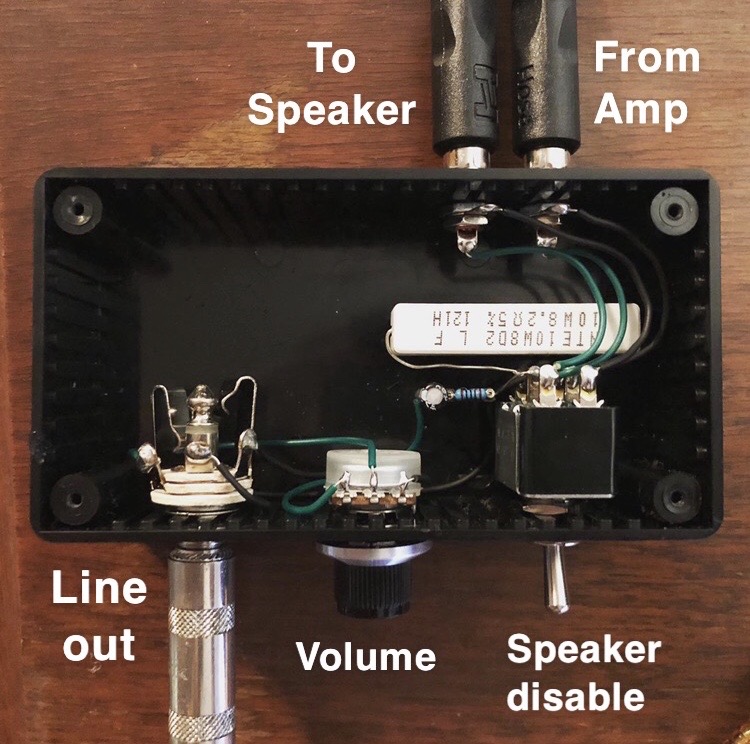

Here is how mine turned out with just the basic components installed:

Basic components installed: Top view

Basic components installed: Front view

Basic components installed: Back view

Step 2: Solder Your Components

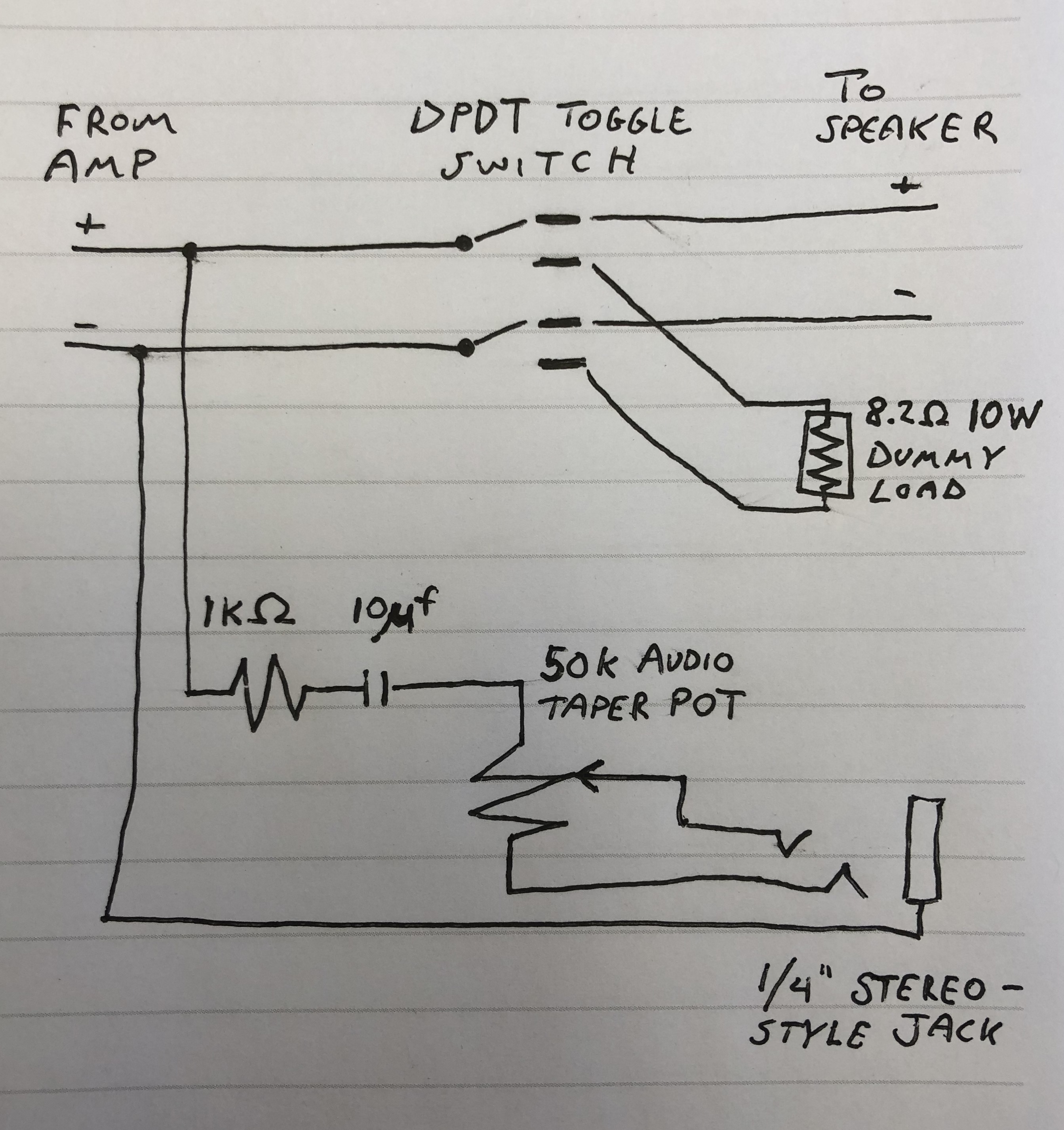

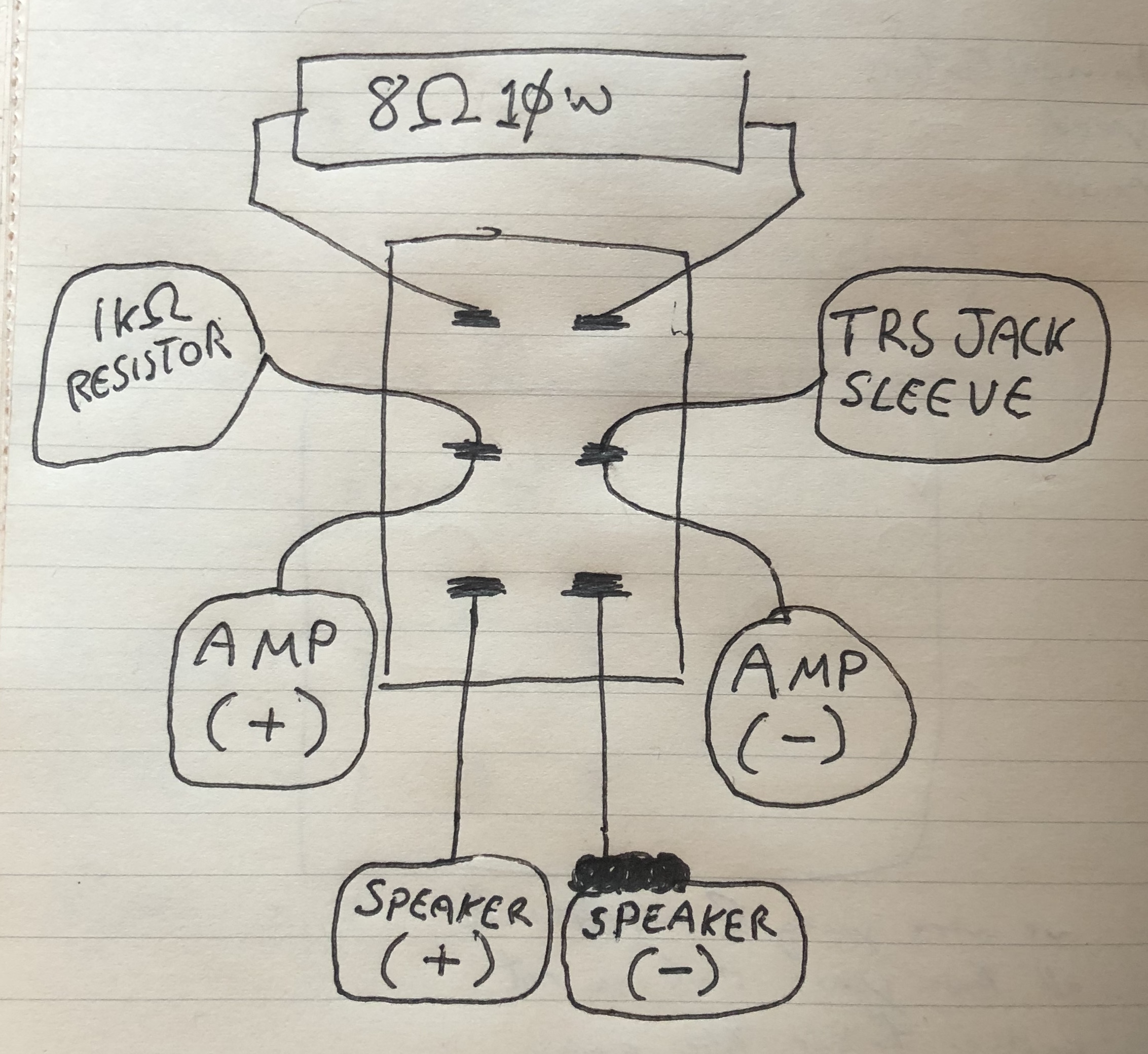

Now you’re ready to start soldering! Here, you’ll want to follow this very professional circuit diagram that I drew in a notebook:

Circuit diagram

I would personally recommend starting from the toggle switch and working out from there. Take a look at this equally-impressive drawing of the toggle switch wiring:

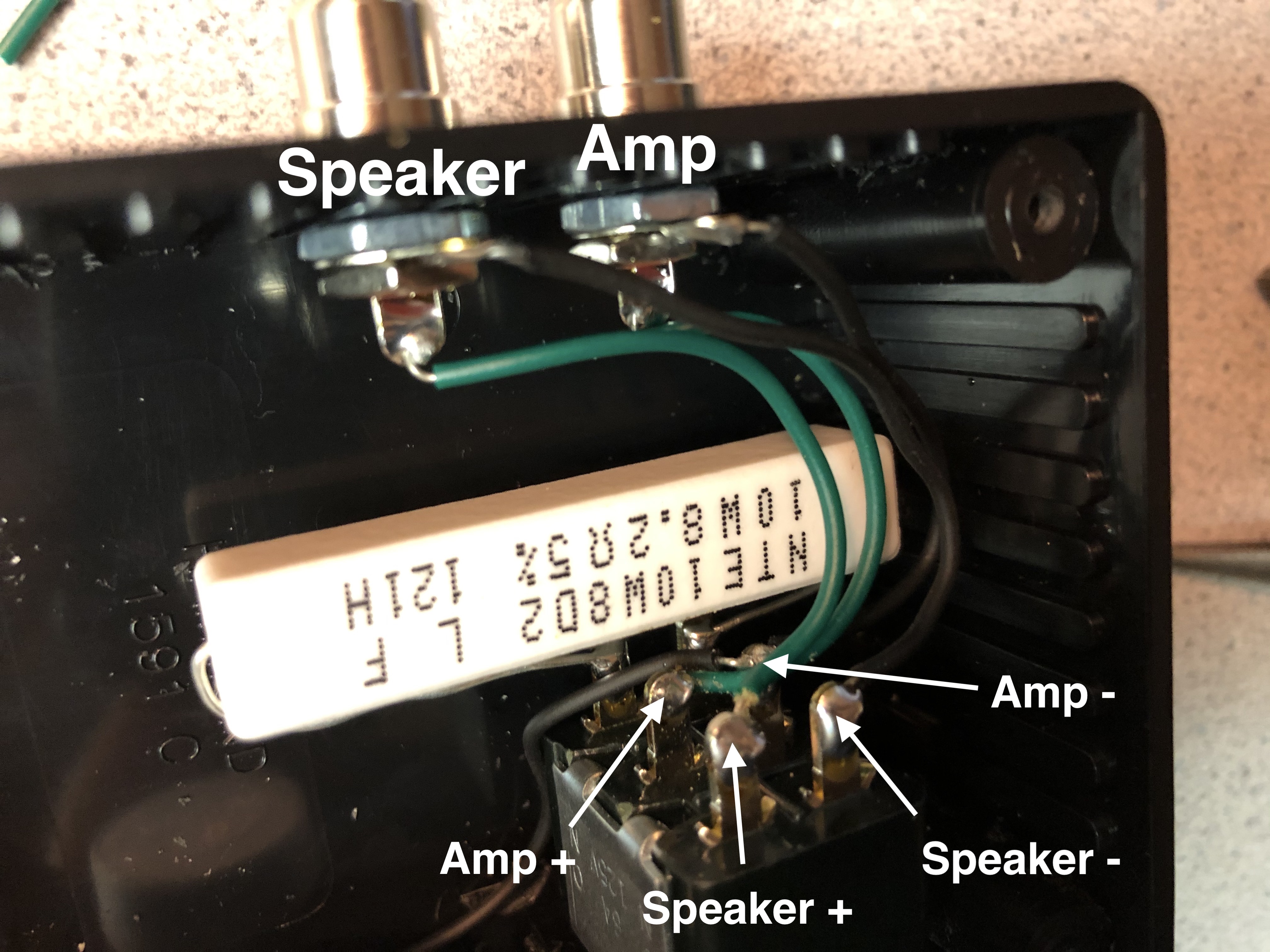

First, solder the big 10Watt power resistor between the bottom two pins on the toggle switch. The orientation of this resistor does not matter. Then solder wires from the input and output RCA jacks to their respective pins as shown here:

Note: The color and type of wire (solid core vs. stranded for example) are not all that important. In these examples, I chose black wires for the negative signal (-) and green wires for the positive signal (+). The reason I did this is because it follows the same color scheme as the speaker wires coming off of the organ (as we’ll see later). But feel free to choose any colors that make sense to you! As long as they help you differentiate between wires, they’ll work just fine.

Now, start making the rest of the connections, following the diagrams above. For connecting the small resistor and the capacitor, I actually used a small section of breakaway female header pins (see below), but you can definitely get away with just soldering the components directly to one another. The main reason I used these headers was to be able to easily swap out values and test which worked the best.

Example of break-away female header pins

Make sure to solder the electrolytic capacitor in the correct direction. The negative side (side with the white stripe) should be connected to the potentiometer and the positive side (without the white stripe, and usually the longer lead wire) should be connected to the 1k resistor.

The rest should be pretty straightforward, just refer to the circuit diagram and the completed picture above.

Step 3: Splice the Speaker Wires

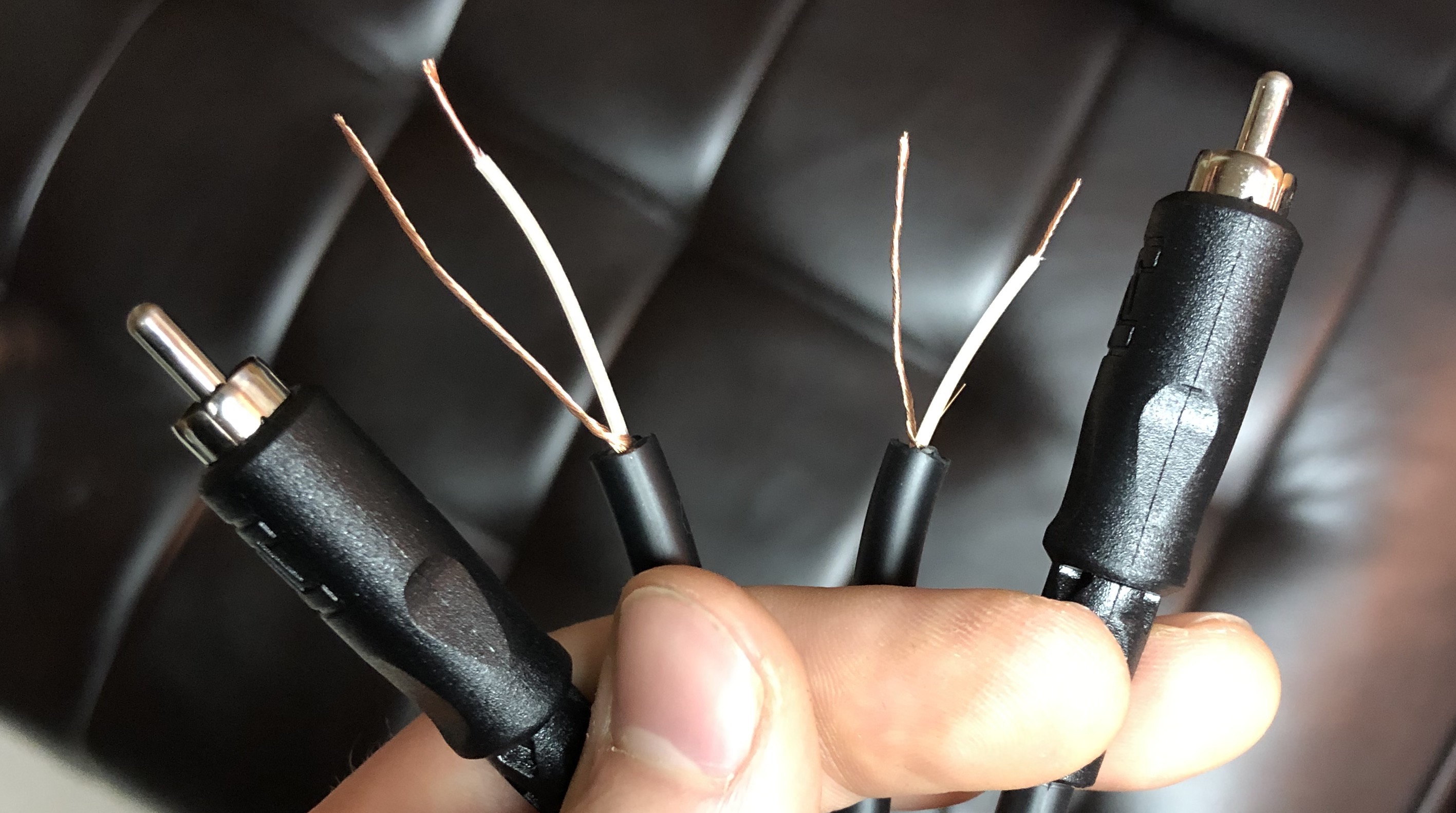

In this step, we’ll be making the one actual modification to the organ: cutting & splicing the speaker wires. Before that, you’ll want to cut your RCA cable and get it ready to attach. I used a single 10′ RCA cable, which I cut pretty much exactly in half (two 5′ halves). You can choose to use a smaller cable if you plan on leaving your line out box inside the back of the organ, but I found that a 10′ cable was perfect for being able to set the box up on top of the organ.

Once you cut your cable, get out the wire stripper and cut off about an inch of the outer black cover. Pull the loose copper strands to the side and twist them neatly. Now cut about half an inch of the white insulation from the positive wire. Your cables should look something like this:

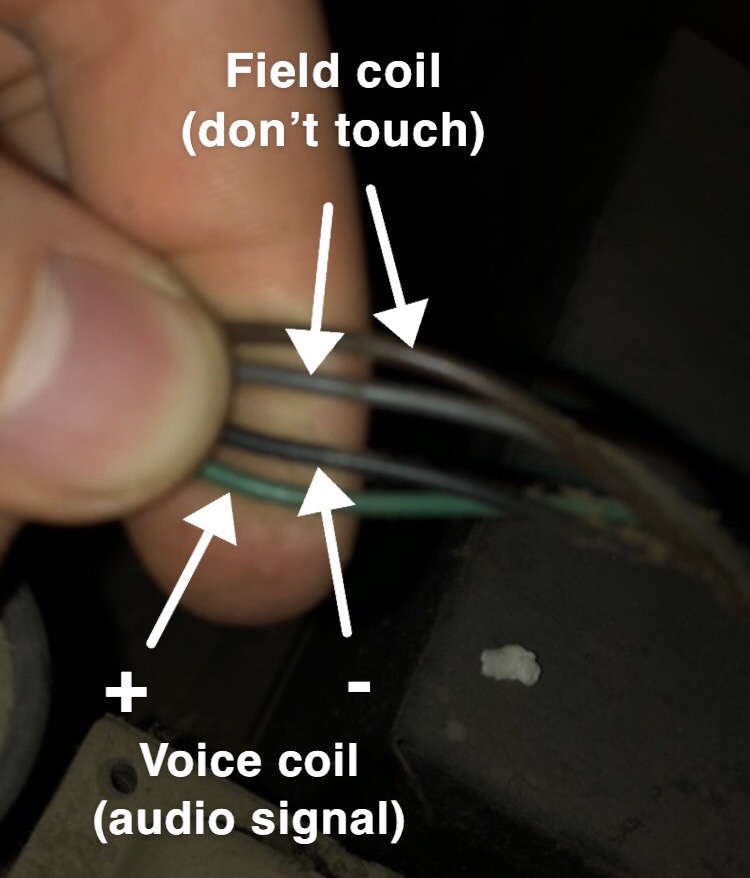

Now, go around to the back of your organ and take a look at the wires coming off of your built in speaker. Depending on the age of your organ and whether any mods were already made, you will find either two wires, or four wires. If you find only two wires, you’re in luck! You’ve already found your signal wires. In my case, there were four wires, which is indicative of an older “EM”-style speaker.

In a nutshell, EM speakers were popular before PM (aka “Permanent Magnet”) speakers became the new standard. EM speakers required two additional “field coil” wires to power an electromagnet. This means you’ll want to be very careful not to accidentally cut the field coil wires. What you’re looking for is a green wire (positive signal) and a black wire (negative signal). The brown and gray wires should be left alone.

Wiring for an EM speaker

Wiring for an EM speaker

NOTE: Before cutting any wires, make sure the organ is powered off/unplugged.

With the organ powered off, go ahead and cut the positive and negative signal wires and strip the insulation about a half inch back. Solder one RCA cable half to the black and green wires coming from the speaker and the other RCA cable half to the black and green wires coming from the amp. The green wire should connect with the positive white insulated RCA wire. The black wire should connect with the negative uninsulated RCA wire.

When soldering these wires, it’s a good idea to insulate them in some way. Ideally, you’ll do this with a few pieces of heat-shrink tubing. Alternatively, you could use electrical tape.

That’s it! Plug in the RCA cables to your line out box and fire up your organ.